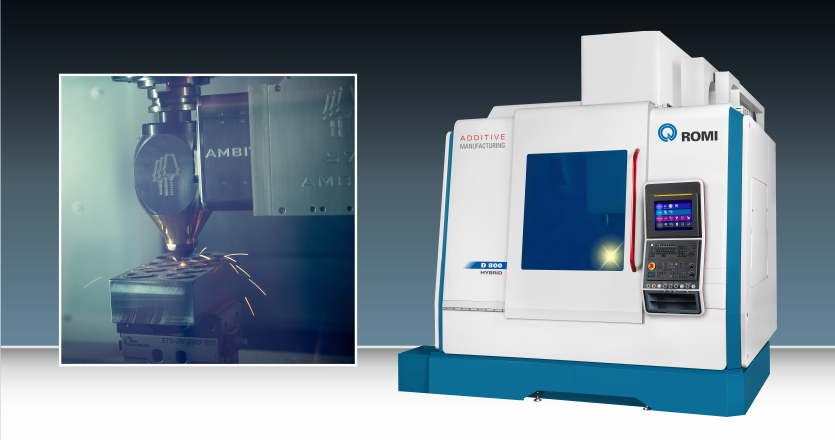

ROMI D Hybrid Series

Additive Manufacturing (3D Metallic Printing)

ROMI D Hybrid Series

Presentation

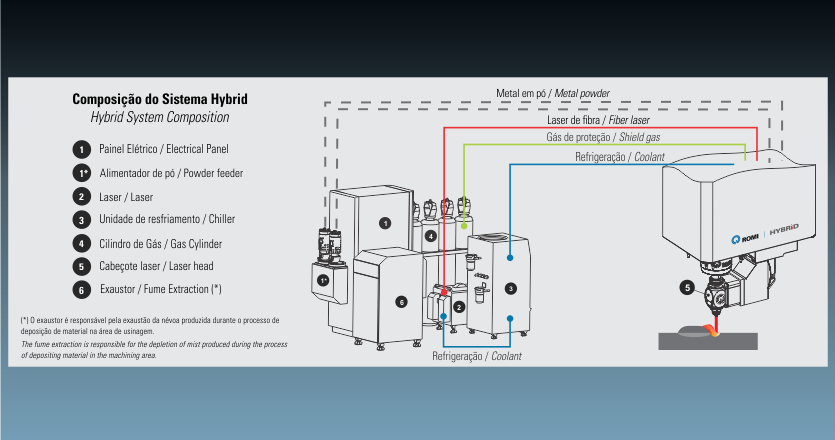

ROMI D Series Hybrid Machining Centers combine machining operations and additive manufacturing (3D metallic printing) in a single piece of equipment.

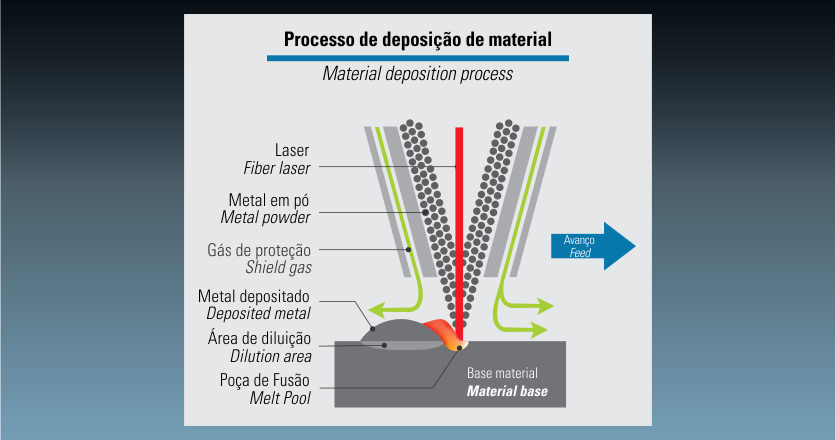

- Materials can be added in the exact amount to achieve the desired profile, and later machined;

- Savings in the use of high-cost materials;

- Low-temperature transmission to the part, avoiding possible thermal cracks;

- Performs engraving and texturing operations;

It is possible to add materials of greater resistance in certain areas of greater wear, increasing the durability of the parts or components, as in stamping tools.

ROMI D Hybrid Series

Main Technical Features

| ROMI D 800 | ROMI D 1000 | ROMI D 1250 | ||

|---|---|---|---|---|

| Spindle taper | ISO | 40 | 40 | 40 |

| Speed range | rpm | 10 to 10.000 or 15 to 15.000 | 10 to 10.000 or 15 to 15.000 | 10 to 10.000 or 15 to 15.000 |

| Rapid traverse (X / Y / Z axes) | ipm | 1,575 | 1,575 | 1,575 |

| Superior table travel (X axis) | in | 31.5 | 40 | 50 |

| Installed power (Hybrid Headstock) | kW | 1,5 | 1,5 | 1,5 |

| Wave Leight (Hybrid Headstock) | nanometro | 1,070 | 1,070 | 1,070 |

ROMI D Hybrid Series

Videos

Consult an expert

Do you need more information about this product? Find here the nearest specialist or send a message.