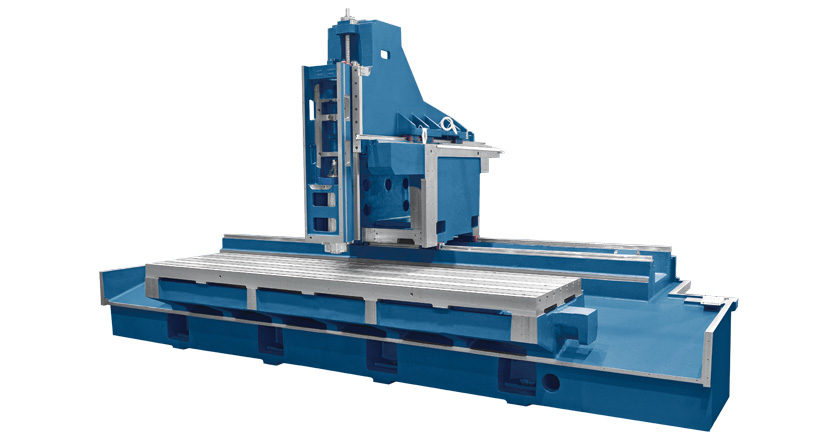

ROMI DCM 3000

Vertical Machining Centers

ROMI DCM 3000

Presentation

The ROMI DCM 3000 is a moving column vertical machining center and is equipped with a SIEMENS CNC. Featuring a fixed table, it is designed to machine long parts with a high degree of accuracy, without any change of the machine’s geometric accuracy.

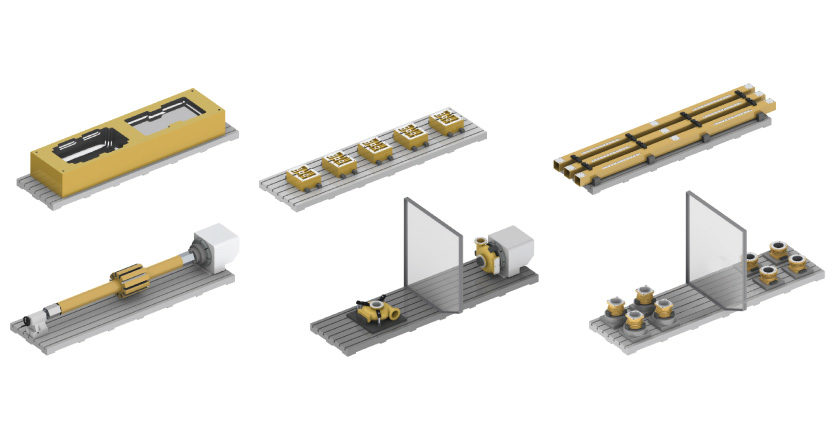

It allows working in two distinct areas of the table (swinging mode), where a metal partition could be installed on the center of the stroke of the X-axis, creating two distinct machining areas. This allows you to perform load and unload of parts in one area, while the other part is machined in the other area, resulting in significant productivity improvements.

ROMI DCM 3000

Main Technical Features

| ROMI DCM 3000 | ||

|---|---|---|

| Spindle taper | ISO | 40 |

| Speed ranges | rpm | 6.000 |

| Rapid traverse (X/Y axes) | m/min (in/min) | 30 (1.181) |

| Rapid traverse (Z axis) | m/min (in/min) | 24 (945) |

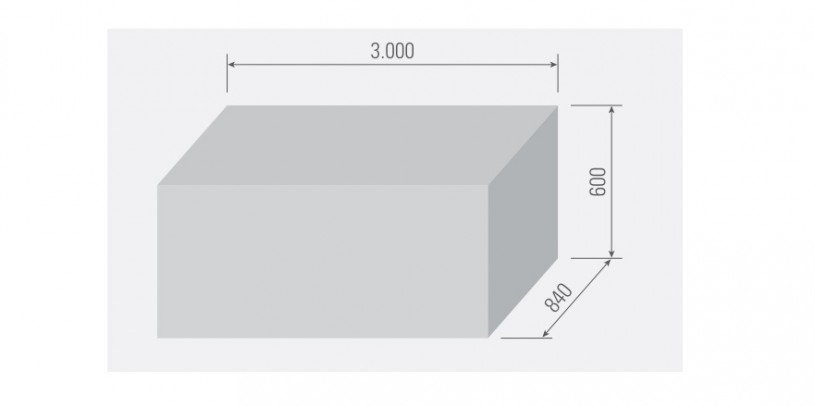

| Table surface | mm (in) | 3.200 x 840 (126 x 33) |

| Tools capacity | - | 30 (40/60 opt) |

| Main motor AC (continous rating) | hp / kW | 30 / 22 |

ROMI DCM 3000

Catalogues

Consult an expert

Do you need more information about this product? Find here the nearest specialist or send a message.