Romi’s new hybrid machines perform additive and subtractive operations

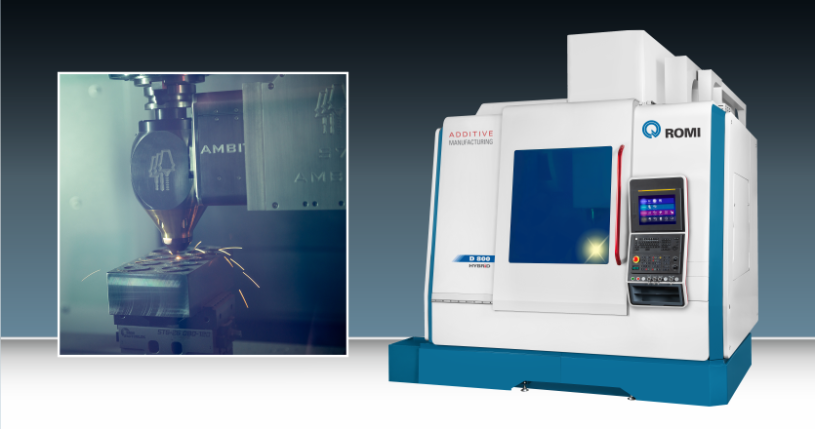

Romi has introduced a line of hybrid machine tools that combine traditional machining operations with 3D metallic additive manufacturing.

Three Generation D vertical machining centers—the D 800, D 1000, and D 1250—form the basis for this family of hybrids. They feature heavy cast bases; roller guides on all axes; direct-drive spindles; and have a maximum machining volume of 31 by 24 by 25 in., 40 by 24 by 25 in., and 50 by 24 by 25 in., respectively.

Switching to AM operation involves swapping out a tool with the machine’s 3D printing head. An automatic toolchanger brings the head into position then the laser-deposition-AM process begins. Material can be added to the workpiece in the exact profile, amount, and location desired, reports the manufacturer.

The machines are recommended for part repair, adding features, and intricate work in which subtractive manufacturing would consume too much time and material.

Romi teamed with Hybrid Manufacturing Technologies—developer of the Ambit additive head—to design the hybrids.